Innovations Driving Global Production Sectors

The global production landscape is undergoing significant transformation, driven by a continuous wave of innovations across various sectors. These advancements are reshaping how goods are conceived, produced, and delivered, influencing everything from large-scale manufacturing facilities to intricate supply chains. Understanding these shifts is crucial for businesses aiming to maintain competitiveness and adapt to evolving market demands. This article explores key innovations that are propelling industrial sectors forward, focusing on the technological, operational, and strategic changes that define modern global production.

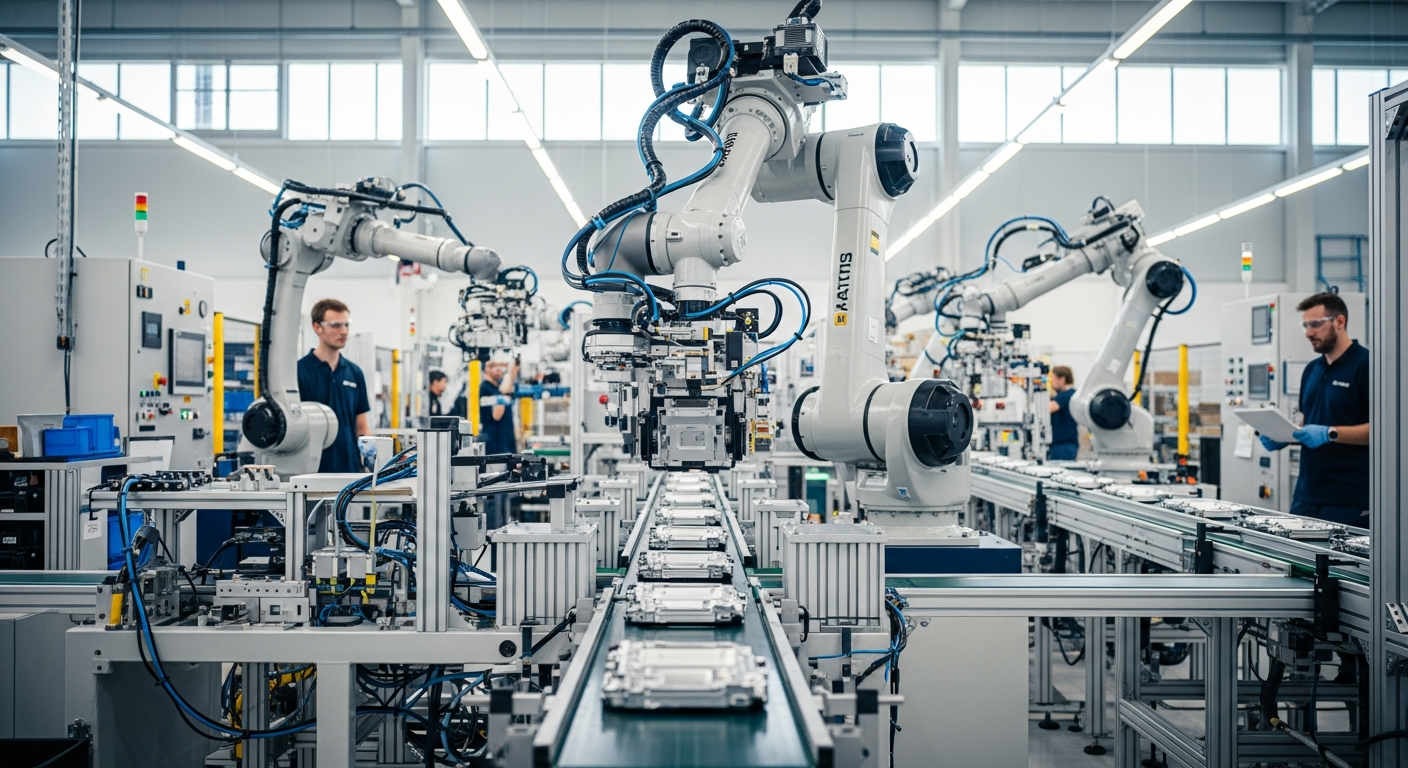

Technological Advancements in Production and Manufacturing

The integration of advanced technology is fundamentally altering manufacturing and production processes worldwide. Concepts such as Industry 4.0, which encompasses the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning, are leading to smarter factories. These digital innovations enable real-time data collection and analysis, predictive maintenance, and optimized resource allocation. Automation, through sophisticated robotics and autonomous systems, is enhancing precision, speed, and safety on the factory floor, allowing for greater customization and higher quality output while reducing human error. Additive manufacturing, or 3D printing, further expands possibilities for rapid prototyping and on-demand production, creating efficiencies and reducing material waste.

Optimizing Logistics and Supply Chain Resilience

Modern logistics and supply chain management are evolving to meet the demands of a global market characterized by increasing complexity and potential disruptions. Innovation in this area focuses on creating more resilient and transparent supply chains. Digital platforms provide end-to-end visibility, enabling better tracking of goods and more efficient route planning. Predictive analytics helps anticipate potential bottlenecks or disruptions, allowing enterprises to proactively adjust their strategies. Furthermore, diversification of sourcing, regionalization of production, and the adoption of smart warehousing solutions contribute to a more robust and adaptable global trade network, safeguarding against unforeseen challenges and ensuring continuity of operations.

Enhancing Operational Efficiency and Processes

Achieving peak operational efficiency is a constant goal for industrial sectors, and new approaches are continuously emerging. Lean manufacturing principles, focused on eliminating waste and maximizing value, are being augmented by digital tools. Process automation, powered by AI and robotic process automation (RPA), streamlines repetitive tasks, freeing up human capital for more complex problem-solving and innovation. The use of digital twins—virtual replicas of physical assets or processes—allows for simulation and optimization before real-world implementation, significantly improving decision-making. Enterprise resource planning (ERP) systems, integrated with these advanced tools, provide a holistic view of operations, enabling better management of resources and workflows across the entire organization.

The Role of Data Analytics in Industrial Management

Data analytics has become an indispensable tool for effective industrial management, transforming raw data into actionable insights. Big data platforms and machine learning algorithms process vast amounts of information generated from production lines, logistics networks, and market trends. This analytical capability supports predictive maintenance, identifying potential equipment failures before they occur and minimizing downtime. It also enhances quality control by pinpointing anomalies in production processes and informs strategic decisions regarding market entry, product development, and resource allocation. By leveraging analytics, businesses can gain a competitive edge through more informed and agile management practices.

Sustainability Initiatives in Global Industrial Sectors

Sustainability is no longer a peripheral concern but a core driver of innovation in global production sectors. Companies are increasingly adopting circular economy principles, which emphasize reducing waste, reusing materials, and recycling products to minimize environmental impact. Green manufacturing practices focus on energy efficiency, reducing carbon footprints, and utilizing renewable energy sources. Ethical sourcing of raw materials and responsible waste management are becoming standard practice, driven by both consumer demand and regulatory pressures. These initiatives not only contribute to environmental protection but also often lead to operational efficiencies and cost savings, fostering a more responsible and future-proof industrial landscape.

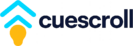

Evolving Workforce Dynamics and Skill Development

The rapid pace of technological innovation is reshaping the global workforce. Automation and digital transformation are altering traditional job roles, creating a demand for new skills while potentially reducing the need for manual labor in certain areas. This shift necessitates a strong focus on upskilling and reskilling programs to equip employees with competencies in areas such as data analysis, robotics operation, and digital literacy. Human-robot collaboration is becoming more common, requiring workers to adapt to new interfaces and workflows. As industrial enterprises embrace these changes, fostering a culture of continuous learning and adaptability is crucial for maintaining a skilled and productive workforce.

The trajectory of global production sectors is undeniably shaped by continuous innovation. From advanced manufacturing technologies and optimized logistics to data-driven management and a strong commitment to sustainability, these developments are creating more efficient, resilient, and responsible industrial ecosystems. Adapting to these changes and embracing new technologies and practices will be key for enterprises worldwide to thrive in an increasingly interconnected and dynamic economic environment.