Mastering Supply Chain Integration for Enhanced Performance

In today's dynamic global market, achieving superior business performance hinges significantly on the effectiveness of a company's supply chain. Supply chain integration is a strategic imperative, focusing on the seamless coordination and collaboration among all entities involved in bringing a product or service to the customer. This holistic approach connects various stages, from raw material sourcing and manufacturing to distribution and final delivery, creating a unified and efficient operational flow designed to enhance overall enterprise efficiency and customer satisfaction. Understanding and implementing robust integration strategies is crucial for sustained growth and competitiveness.

Understanding Supply Chain Integration Principles

Supply chain integration involves the strategic alignment and collaboration of an enterprise with its suppliers, manufacturers, distributors, and customers. At its core, it seeks to optimize the entire flow of goods, services, and information across the supply network. This goes beyond simple transactional relationships, fostering deeper partnerships that aim for shared goals and mutual benefits. Effective integration relies on transparent communication, shared data, and coordinated planning, all contributing to a more cohesive and responsive supply network. A well-defined strategy ensures that each component of the supply chain works in harmony, eliminating bottlenecks and improving overall operational fluidity.

Key Benefits for Manufacturing and Logistics

For manufacturing and logistics sectors, integrated supply chains offer substantial advantages. By connecting production schedules with demand forecasts and raw material supply, manufacturers can achieve greater efficiency, reduce waste, and improve product quality. This synchronization minimizes inventory holding costs and accelerates production cycles. In logistics, integration leads to optimized transportation routes, better warehouse management, and faster delivery times. Enhanced visibility across the entire supply chain allows for proactive problem-solving, reducing disruptions and ensuring timely fulfillment. This ultimately contributes to significant cost savings and improved service levels, directly impacting business growth and market position.

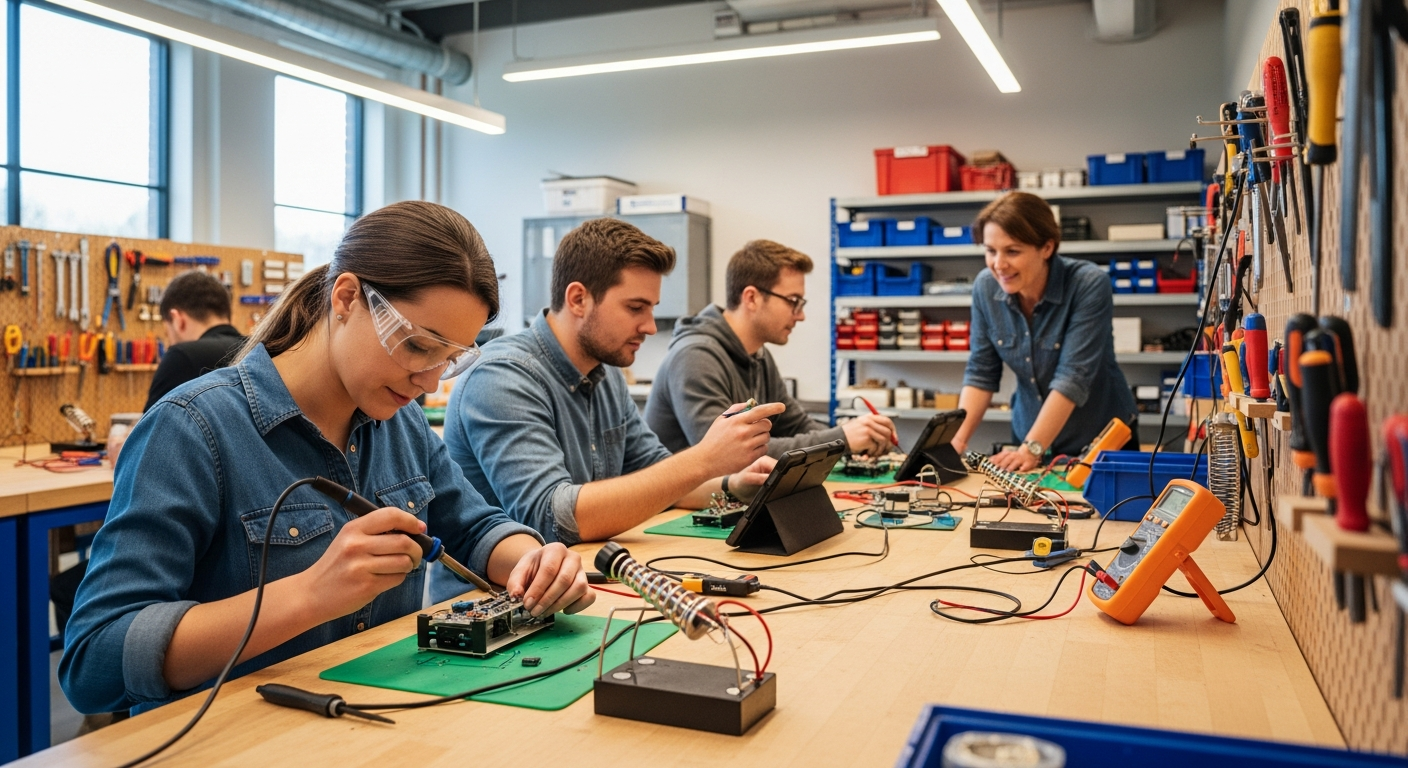

Leveraging Technology for Seamless Enterprise Operations

Technology plays a pivotal role in enabling comprehensive supply chain integration. Digital solutions such as Enterprise Resource Planning (ERP) systems, Supply Chain Management (SCM) software, and cloud-based platforms facilitate real-time data sharing and communication across diverse operations. Automation, powered by robotics and artificial intelligence, streamlines repetitive tasks in manufacturing and warehousing, further boosting efficiency and reducing human error. These technological advancements provide a unified view of the entire supply network, allowing for better decision-making and more agile responses to market changes. The adoption of advanced technology is fundamental for any enterprise aiming to achieve seamless, interconnected operations.

Fostering Innovation and Resilience in Global Trade

An integrated supply chain is a powerful driver for innovation and resilience, particularly in the context of global trade. By fostering close collaboration with partners, businesses can jointly develop new products, improve existing processes, and explore sustainable practices. This environment encourages a culture of continuous improvement and adaptability. Furthermore, an integrated network enhances resilience by providing greater visibility into potential disruptions, such as geopolitical events, natural disasters, or shifts in market demand. Companies can quickly identify vulnerabilities and implement contingency plans, maintaining operational continuity and mitigating financial risks. This strategic advantage is crucial for navigating the complexities of the modern global market.

Data Analytics and Sustainability in Modern Production

Data analytics has become indispensable for optimizing supply chain performance and advancing sustainability goals. By collecting and analyzing vast amounts of data from various points in the supply chain, businesses can gain deep insights into purchasing patterns, production efficiencies, logistics performance, and environmental impact. Predictive analytics can forecast demand more accurately, reduce overproduction, and optimize resource allocation. From a sustainability perspective, analytics helps identify areas for waste reduction, energy conservation, and ethical sourcing. This focus on data-driven decision-making not only enhances operational efficiency and profitability but also supports the development of a more responsible and environmentally conscious production model, aligning with evolving consumer and regulatory expectations.

Operationalizing Integration: Key Provider Solutions

Implementing supply chain integration often involves partnering with technology providers that offer specialized solutions. These providers offer platforms and services designed to connect disparate systems, manage data flows, and enhance collaborative capabilities across the supply network. Their offerings typically include modules for planning, procurement, manufacturing, logistics, and order fulfillment, all integrated into a cohesive system. Selecting the right provider depends on the specific needs of an enterprise, including its size, industry, global reach, and existing IT infrastructure. The goal is to find a solution that supports the strategic objectives of the business while offering scalability and robust support.

| Provider Name | Services Offered | Key Features/Benefits |

|---|---|---|

| SAP | ERP, SCM, Ariba (Procurement) | Comprehensive suite, real-time analytics, global reach |

| Oracle | SCM Cloud, ERP Cloud | AI-driven insights, end-to-end visibility, industry-specific solutions |

| Infor | CloudSuite SCM | Industry-specific focus, advanced planning, multi-enterprise collaboration |

| Blue Yonder | Luminate Platform | AI/ML-driven forecasting, demand planning, fulfillment optimization |

| Manhattan Associates | Supply Chain Commerce Solutions | Warehouse management, transportation management, omnichannel fulfillment |

Mastering supply chain integration is no longer merely an operational advantage but a fundamental requirement for businesses aiming for sustained success in a competitive global landscape. By embracing strategic collaboration, leveraging cutting-edge technology, and making data-driven decisions, organizations can build resilient, efficient, and innovative supply chains. This integrated approach not only optimizes core operations from production to commerce but also positions an enterprise for continuous growth and adaptability in an ever-evolving market, ensuring long-term viability and enhanced performance across all facets of the business.