Material Science Innovations in Car Manufacturing

The automotive industry is undergoing a profound transformation, driven significantly by advancements in material science. These innovations are not merely incremental improvements but represent fundamental shifts in how vehicles are designed, engineered, and manufactured. From enhancing safety and fuel efficiency to enabling the development of electric and autonomous vehicles, new materials are at the core of shaping the future of mobility. Understanding these developments offers insight into the evolving landscape of transport and the continuous pursuit of performance, sustainability, and user experience.

Advancements in Lightweight Materials for Automotive Performance

The pursuit of lighter vehicles has been a continuous goal in automotive manufacturing, directly impacting fuel efficiency and overall performance. Material science innovations have led to the widespread adoption of advanced high-strength steels (AHSS), aluminum alloys, and carbon fiber composites. These materials offer superior strength-to-weight ratios compared to traditional steel, allowing manufacturers to reduce vehicle mass without compromising structural integrity. The integration of these lightweight solutions is crucial for improving acceleration, handling, and braking, contributing to a more dynamic driving experience. Furthermore, lighter vehicles require less energy to move, which is particularly beneficial for electric vehicles as it extends range and reduces battery size requirements, a key aspect of future electric mobility.

Enhancing Vehicle Safety and Durability through Material Science

Safety remains a paramount concern in vehicle design and engineering. Material science plays a vital role in developing structures that can better absorb impact energy during collisions, protecting occupants. Beyond lightweighting, advanced materials contribute to enhanced durability and crashworthiness. For instance, specific grades of steel and aluminum are engineered to deform predictably under stress, directing forces away from the passenger compartment. Innovations also extend to interior materials, with developments in fire-resistant fabrics and energy-absorbing foams that further contribute to occupant safety. The ongoing research in material science aims to create even more resilient and protective vehicle architectures for all forms of transport.

Sustainable Materials in Electric Vehicle Manufacturing

As the automotive industry shifts towards electric vehicles (EVs), the focus on sustainability in manufacturing processes and materials becomes increasingly important. Material science is addressing this by exploring and implementing eco-friendly alternatives. This includes the use of recycled plastics, natural fibers, and bio-based composites for various interior and exterior components, reducing reliance on virgin fossil fuel-derived materials. Battery technology itself is a significant area of material innovation, with research into more efficient, longer-lasting, and recyclable battery chemistries. The development of sustainable materials aligns with the broader goals of reducing the environmental footprint of automotive production and supporting a circular economy for vehicles.

Material Innovations for Future Mobility and Urban Transport

Future mobility concepts, including autonomous vehicles and integrated urban transport systems, are heavily reliant on new material capabilities. Material innovations are enabling radical changes in vehicle design, allowing for more flexible interiors, advanced sensor integration, and improved aerodynamic forms. For autonomous vehicles, materials that can house and protect sensitive electronic components, while also allowing for seamless signal transmission, are critical. Furthermore, the development of smart materials with self-healing properties or integrated sensors could revolutionize vehicle maintenance and safety. These advancements are paving the way for a new era of transport that is not only efficient and safe but also highly adaptable to the evolving needs of urban environments and connectivity.

Cost and Provider Insights in Advanced Automotive Materials

The adoption of advanced materials in car manufacturing often involves higher initial costs compared to traditional steel. However, these costs are frequently offset by benefits such as improved fuel efficiency, enhanced safety, and extended product life cycles. The material science sector, which supplies the automotive industry, includes a diverse range of companies specializing in different material types. For instance, large chemical and materials companies like BASF, Covestro, and LyondellBasell are key players in polymers and composites. Steel giants such as ArcelorMittal and Nippon Steel innovate in advanced high-strength steels, while aluminum producers like Alcoa and Novelis focus on lightweight aluminum alloys for vehicle bodies. The precise cost estimation for integrating specific materials varies greatly depending on the volume, complexity of manufacturing, and specific application within a vehicle. Continuous innovation aims to reduce the cost barriers for widespread adoption of these advanced solutions.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

| Product/Service | Provider | Cost Estimation (per kg, illustrative) |

|---|---|---|

| Advanced High-Strength Steel | ArcelorMittal | $1.00 - $3.00 |

| Aluminum Alloys | Novelis | $2.50 - $5.00 |

| Carbon Fiber Composites | Toray Industries | $15.00 - $50.00 |

| Recycled Plastics | LyondellBasell | $1.50 - $4.00 |

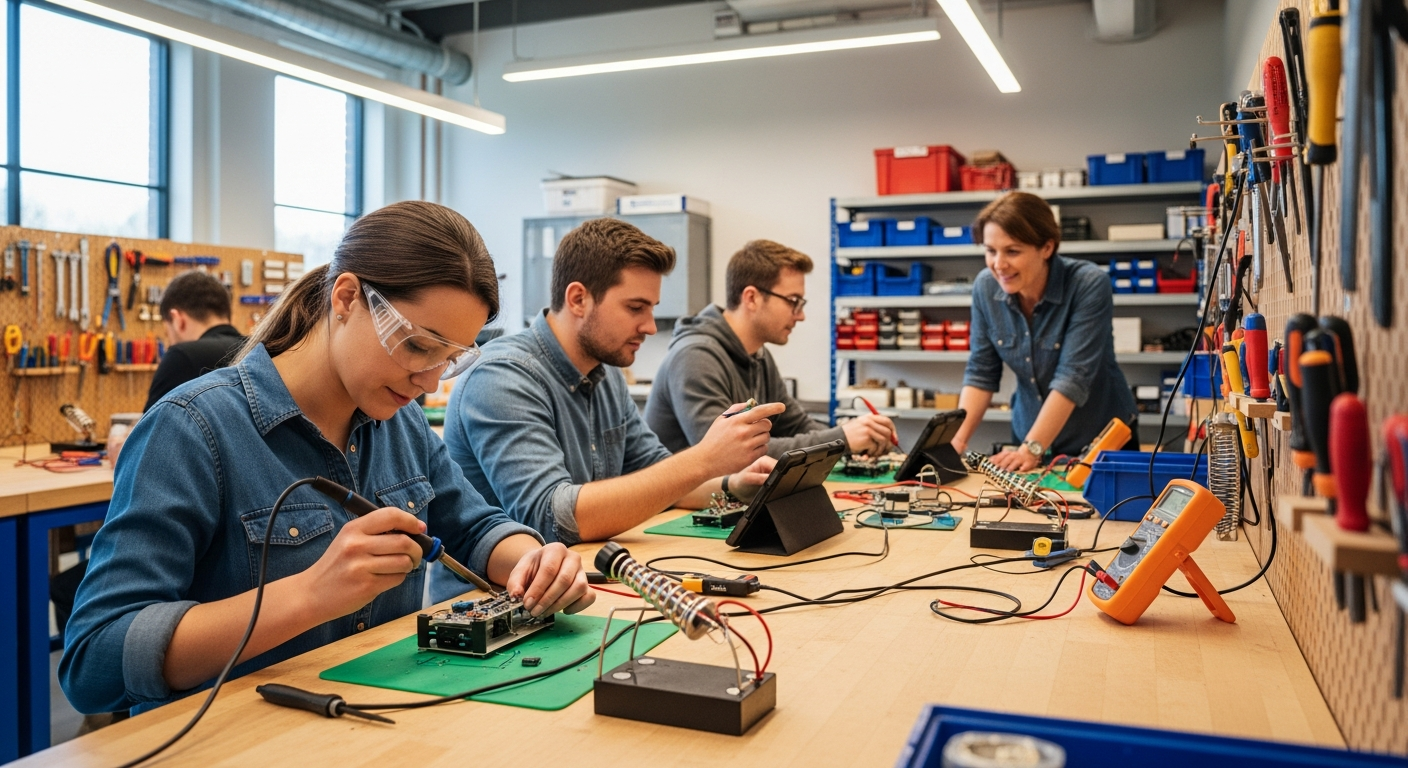

The Role of Engineering in Material Integration

The successful integration of new materials into vehicle manufacturing requires sophisticated engineering processes. It’s not just about selecting a material, but understanding how it behaves under various conditions, how it can be formed and joined with other materials, and how it contributes to the overall vehicle structure. Advanced simulation tools and manufacturing techniques, such as additive manufacturing (3D printing) and specialized welding methods, are critical for working with these novel materials. Engineering expertise ensures that the theoretical benefits of material science innovations are realized in practical, mass-produced vehicles, optimizing for factors like crash performance, noise reduction, and long-term durability.

In conclusion, material science innovations are fundamental to the evolution of car manufacturing, driving progress across multiple fronts. From enhancing performance and safety to fostering sustainability and enabling the next generation of intelligent and connected vehicles, new materials are redefining what is possible in the automotive sector. These ongoing developments underscore a commitment to creating more efficient, safer, and environmentally responsible transport solutions for the global population, shaping the future landscape of personal and public mobility.