Micro-Customization: Revolutionizing Industrial Production

The era of mass customization is giving way to a new paradigm: micro-customization. This innovative approach to manufacturing allows companies to tailor products to individual consumer preferences at scale, without sacrificing efficiency or profitability. By leveraging advanced technologies and reimagining production processes, businesses are now able to offer unprecedented levels of personalization, creating unique value propositions and fostering deeper customer relationships.

The Evolution of Customization in Manufacturing

The concept of customization in manufacturing is not new. For decades, businesses have sought ways to differentiate their products and cater to diverse consumer preferences. However, the traditional approach to customization often involved significant trade-offs between personalization and production efficiency. Mass production allowed for economies of scale but limited product variety, while bespoke manufacturing offered high levels of customization but at premium prices and longer lead times.

As technology advanced, mass customization emerged as a middle ground, allowing companies to offer a range of pre-defined options to consumers. While this approach expanded consumer choice, it still fell short of true personalization. Micro-customization takes this concept further, enabling businesses to tailor products to individual specifications without compromising on production speed or cost-effectiveness.

Enabling Technologies for Micro-Customization

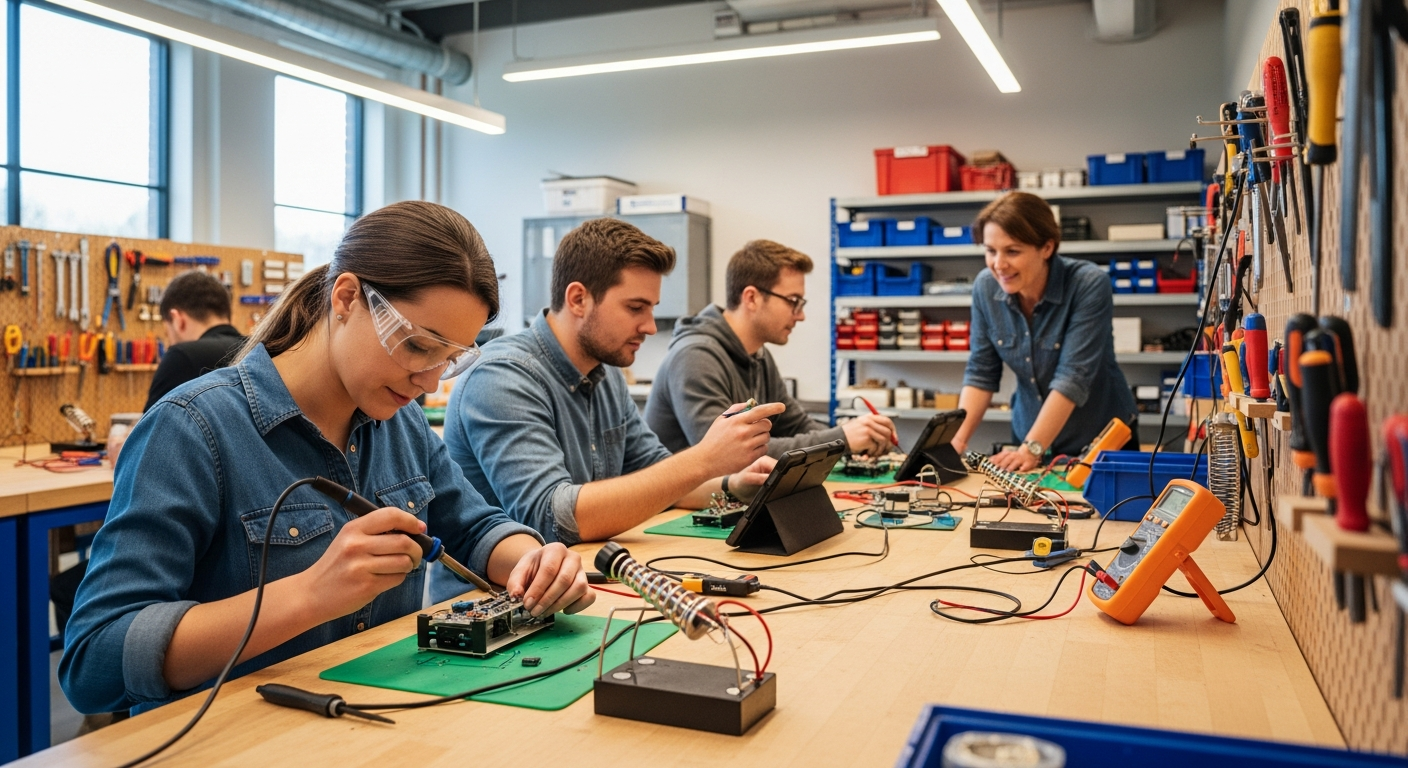

The rise of micro-customization has been made possible by a convergence of cutting-edge technologies. Advanced manufacturing techniques, such as 3D printing and additive manufacturing, allow for the production of complex, customized components with minimal setup time and tooling costs. These technologies enable businesses to produce small batches or even single units of customized products efficiently.

Sophisticated software systems, including advanced CAD/CAM tools and parametric design software, facilitate rapid product configuration and design modifications. These systems can automatically generate production-ready designs based on customer inputs, streamlining the customization process and reducing the need for manual intervention.

Data analytics and artificial intelligence play a crucial role in micro-customization by analyzing customer preferences, predicting trends, and optimizing production processes. By leveraging these technologies, businesses can anticipate demand for specific customization options and adjust their production plans accordingly, minimizing waste and maximizing efficiency.

Reimagining the Production Line

Micro-customization necessitates a fundamental rethinking of traditional production line concepts. Instead of fixed, linear assembly lines designed for high-volume production of standardized products, micro-customization requires flexible, modular production systems that can easily adapt to changing product specifications.

One approach gaining traction is the implementation of reconfigurable manufacturing systems (RMS). These systems consist of modular production units that can be quickly rearranged or reprogrammed to accommodate different product variations. This flexibility allows manufacturers to switch between different customization options with minimal downtime, enabling efficient production of small batches or even single units.

Another key aspect of micro-customization is the integration of real-time data throughout the production process. By leveraging Internet of Things (IoT) sensors and advanced monitoring systems, manufacturers can track each customized product as it moves through the production line, ensuring that the correct specifications are applied at each stage and maintaining high quality standards despite the increased complexity of individualized production.

Customer Engagement and Co-Creation

Micro-customization goes beyond mere product personalization; it represents a shift towards collaborative product development between businesses and consumers. By involving customers in the design process, companies can create products that truly resonate with individual preferences and needs.

Digital platforms and augmented reality technologies are enabling new forms of customer engagement in the customization process. For example, some furniture manufacturers now offer virtual design tools that allow customers to visualize and modify products in real-time, experimenting with different materials, colors, and configurations before finalizing their order.

This level of engagement not only enhances customer satisfaction but also provides valuable data insights for businesses. By analyzing customer choices and preferences, companies can identify emerging trends, refine their product offerings, and optimize their production processes to better align with market demands.

Challenges and Considerations

While micro-customization offers significant opportunities, it also presents several challenges that businesses must address. One primary concern is managing the increased complexity in supply chain and inventory management. With potentially unlimited product variations, traditional forecasting and inventory models may no longer be sufficient.

To overcome this challenge, some companies are adopting just-in-time manufacturing principles and implementing advanced supply chain management systems that can handle the complexity of micro-customized production. Additionally, the use of digital twins and simulation technologies can help optimize production planning and resource allocation for customized orders.

Another consideration is the need for robust quality control processes. With each product potentially unique, traditional quality assurance methods based on sampling may not be adequate. Manufacturers must implement comprehensive in-line quality monitoring systems and leverage data analytics to ensure consistency and reliability across all customized products.

Key Strategies for Implementing Micro-Customization

• Invest in flexible manufacturing technologies that can easily adapt to changing product specifications

• Develop modular product architectures that allow for easy customization of individual components

• Implement advanced digital platforms to facilitate customer engagement and co-creation

• Leverage data analytics and AI to optimize production processes and predict customization trends

• Foster a culture of innovation and agility within the organization to respond quickly to changing customer demands

As micro-customization continues to gain traction across industries, it is poised to redefine the relationship between businesses and consumers. By offering unprecedented levels of personalization at scale, companies can create unique value propositions that set them apart in crowded marketplaces. However, success in this new paradigm requires a holistic approach that encompasses technological innovation, process redesign, and a deep understanding of customer needs and preferences.

The businesses that can successfully navigate the challenges of micro-customization and harness its potential will be well-positioned to thrive in an increasingly personalized and dynamic market landscape. As we move forward, the ability to offer tailored products efficiently and at scale may become not just a competitive advantage, but a necessity for survival in many industries.