Navigating Global Supply Chain Complexities

The modern global economy is characterized by intricate and interconnected supply chains, which are essential for the movement of goods and services across borders. However, these complex networks are increasingly susceptible to various disruptions, including geopolitical shifts, economic volatility, natural disasters, and technological advancements. Understanding and effectively navigating these complexities is crucial for businesses aiming to maintain operational continuity, foster resilience, and sustain growth in an ever-evolving global market landscape. This article explores key strategies and considerations for managing the multifaceted challenges inherent in today's global supply chains, emphasizing adaptability and foresight.

Manufacturing and Production Strategies in a Global Context

Global manufacturing and production strategies are fundamental to a robust supply chain. Businesses must consider factors like localized production, regional hubs, and diversified sourcing to mitigate risks associated with over-reliance on a single geographic area. Effective enterprise resource planning (ERP) systems are vital for coordinating production schedules, managing inventory across multiple sites, and ensuring that manufacturing operations are aligned with global demand and market fluctuations. This approach allows for greater agility and responsiveness to unforeseen events, safeguarding production continuity.

The Role of Logistics and Operations in Supply Chain Resilience

Efficient logistics and streamlined operations are the backbone of any successful global supply chain. This involves optimizing transportation routes, warehousing solutions, and distribution networks to minimize lead times and reduce costs. Building resilience into these operations means anticipating potential disruptions—such as port congestion, freight capacity shortages, or regulatory changes in trade—and developing contingency plans. Investing in robust operational frameworks that can adapt quickly to changing conditions is paramount for maintaining the flow of goods and services worldwide.

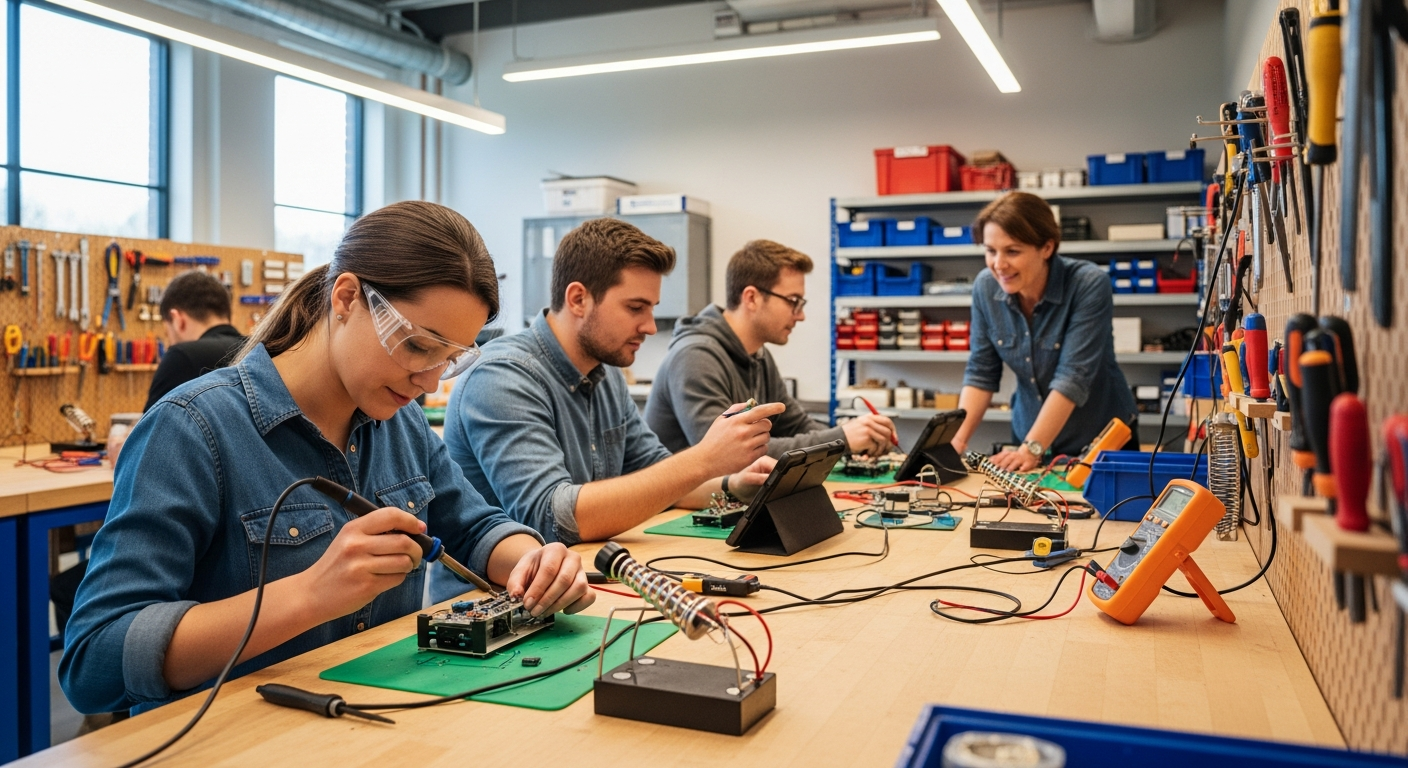

Leveraging Technology and Automation for Enhanced Efficiency

Technology and automation play a transformative role in enhancing supply chain efficiency and transparency. Advanced analytics tools can provide real-time insights into inventory levels, demand patterns, and potential bottlenecks, enabling proactive decision-making. Automation in warehouses, factories, and logistics processes can significantly reduce manual errors, speed up operations, and improve overall productivity. Implementing innovative technologies like blockchain for traceability or AI for demand forecasting can revolutionize workflows, making the entire supply chain more intelligent and responsive.

Developing Sustainable Supply Chain Management Practices

Sustainability has become a critical component of modern supply chain management. This involves not only environmental considerations, such as reducing carbon footprints and waste, but also social and ethical practices throughout the supply network. Businesses are increasingly focused on sourcing materials responsibly, ensuring fair labor practices, and promoting circular economy principles. A strategic commitment to sustainability can enhance brand reputation, attract environmentally conscious consumers, and often lead to long-term operational efficiencies and cost savings.

Data Analytics and Strategic Decision-Making

In the complex global market, data analytics is indispensable for informed strategic decision-making. By analyzing vast amounts of data related to supply, demand, economic indicators, and market trends, companies can gain a deeper understanding of their operational landscape. Predictive analytics can help anticipate future challenges and opportunities, allowing businesses to adjust their supply chain strategy proactively. This data-driven approach supports better inventory management, optimizes pricing strategies, and strengthens overall enterprise planning, leading to more resilient and competitive operations.

Adapting to Global Market Dynamics and Trade Workflows

Global supply chains operate within a dynamic environment shaped by constantly evolving market dynamics and international trade policies. Economic shifts, trade agreements, and geopolitical events can significantly impact sourcing, production, and distribution. Businesses must continuously monitor these factors and adapt their workflows and strategies accordingly. This includes diversifying supplier bases, understanding regional market nuances, and building flexible trade compliance programs to navigate tariffs, quotas, and customs regulations effectively. A proactive approach to these external forces ensures sustained market access and operational stability.

Navigating the complexities of global supply chains requires a holistic and adaptive approach. By focusing on resilient manufacturing and production, efficient logistics and operations, leveraging technology and automation, embracing sustainability, utilizing data analytics for strategic insights, and adapting to dynamic market and trade conditions, businesses can build robust and future-proof supply networks. Continuous innovation and a commitment to strategic management are key to thriving in the intricate global economy.