Optimizing Global Production Chains for Efficiency

In an increasingly interconnected global economy, the efficiency of production chains is a critical factor for business success across various industries. Companies worldwide are continually seeking strategies to streamline their operations, reduce waste, and enhance responsiveness to market demands. Understanding the multifaceted components of a global production chain, from raw material sourcing to final product delivery, is essential for identifying areas ripe for improvement and sustained growth.

Understanding the Global Manufacturing Landscape

Global manufacturing involves a complex web of processes spanning multiple geographical locations, from design and raw material acquisition to assembly and distribution. This distributed approach allows businesses to leverage specialized skills, access diverse resources, and tap into new markets. However, it also introduces challenges related to coordination, quality control, and geopolitical factors. Effective management of this intricate system is paramount for maintaining a competitive edge in today’s dynamic market.

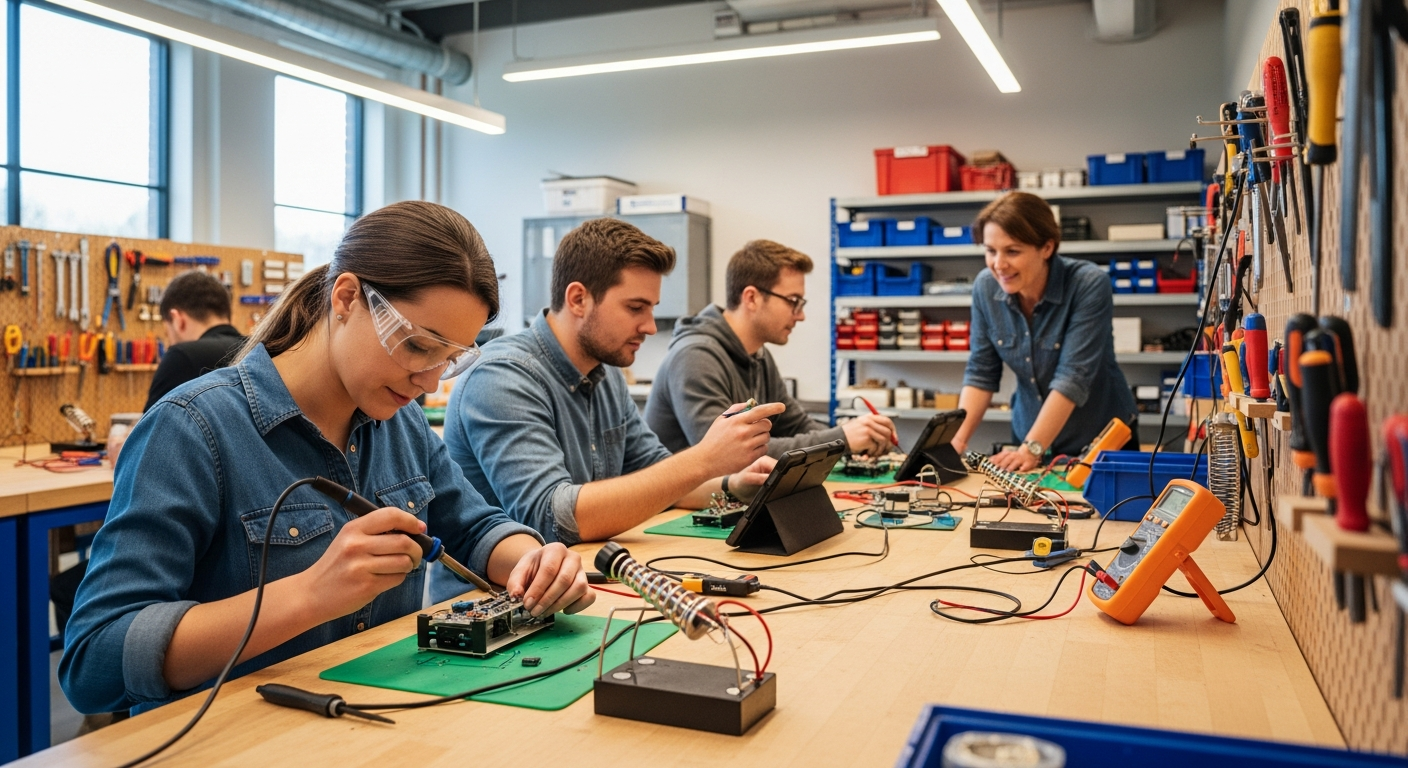

Enhancing Production Efficiency Through Technology and Automation

Achieving higher efficiency in manufacturing and production requires a strategic embrace of modern technology and automation. Implementing advanced robotics, artificial intelligence (AI), and the Internet of Things (IoT) can significantly optimize various stages of the production process. For instance, predictive maintenance powered by AI can minimize downtime, while automated assembly lines can boost output and reduce human error. These innovations not only improve speed and accuracy but also contribute to better resource utilization and reduced operational costs within an enterprise.

Streamlining Supply Chain and Logistics Operations

Optimizing the supply chain and logistics is fundamental to an efficient global production chain. This involves meticulously planning the movement of goods, information, and finances from the point of origin to the point of consumption. Key strategies include demand forecasting, inventory management, and robust transportation networks. Companies are increasingly adopting digital supply chain platforms that provide real-time visibility, enabling quicker decision-making and better responsiveness to disruptions. This proactive management of operations helps reduce lead times and ensures timely delivery, which is vital for customer satisfaction and commerce.

Navigating Global Market Dynamics and Trade

Operating in a global market necessitates a keen awareness of international economy dynamics, trade policies, and regulatory frameworks. Geopolitical shifts, tariffs, and fluctuating currency exchange rates can all impact the profitability and viability of production chains. Businesses must develop flexible strategyies that allow them to adapt quickly to changes, perhaps by diversifying sourcing locations or establishing regional hubs. Understanding and mitigating these risks is crucial for sustained growth and development in the industry.

The Role of Data Analytics in Strategic Management

In the pursuit of optimizing global production chains, the role of data management and analytics cannot be overstated. Collecting and analyzing data from various operational points—from production floors to logistics networks and market feedback—provides invaluable insights. Advanced analytics can identify bottlenecks, predict potential issues, and uncover opportunities for process innovation. This data-driven approach enables enterprises to make informed strategic decisions, leading to continuous improvement and enhanced overall efficiency across the entire industry spectrum.

Optimizing global production chains is an ongoing endeavor that requires a holistic approach, integrating technology, strategy, and management across all facets of an enterprise. By focusing on efficiency, fostering innovation, and adapting to the complexities of the global market and economy, businesses can build resilient and responsive supply chains that support sustainable growth and competitive advantage.