Risk Mitigation in Supply Chain Networks

Modern supply chains are intricate global networks, constantly exposed to a myriad of potential disruptions ranging from natural disasters and geopolitical shifts to technological failures and economic volatility. Effectively managing these risks is not merely a reactive measure but a strategic imperative for businesses aiming to maintain operational continuity, protect their reputation, and ensure long-term sustainability and competitiveness in an increasingly interconnected world. Understanding the landscape of potential threats and developing robust mitigation strategies is crucial for any enterprise engaged in global commerce and industry.

Understanding Supply Chain Vulnerabilities

Global supply chains, by their very nature, introduce numerous points of potential failure. These vulnerabilities can stem from various sources, including natural phenomena such as earthquakes, floods, or pandemics, which can halt production or disrupt logistics and trade routes. Geopolitical tensions, trade wars, and economic downturns also pose significant threats, impacting resource availability, market access, and overall operational stability. Additionally, reliance on single suppliers or concentrated production hubs can amplify the impact of localized disruptions, making the entire network susceptible to significant setbacks. Identifying these weak points is the first step in developing effective mitigation strategies.

Strategic Approaches to Risk Management

Effective risk mitigation in supply chain networks requires a proactive and comprehensive strategy. This begins with thorough risk assessment, mapping out potential disruptions and their likely impact on operations. Developing a robust risk management framework involves identifying critical nodes, understanding interdependencies, and creating contingency plans for various scenarios. Strategies often include diversifying supplier bases, holding strategic inventory buffers, and implementing flexible production capabilities. A strong management commitment to these strategies ensures that risk planning is integrated into daily operations and long-term enterprise development.

Leveraging Technology for Enhanced Resilience

Technology plays a pivotal role in building resilient supply chains. Advanced analytics, artificial intelligence, and machine learning can predict potential disruptions by analyzing vast datasets, offering early warnings for issues like weather events or demand fluctuations. Automation in logistics and production can reduce human error and increase efficiency, while blockchain technology can enhance transparency and traceability across the entire supply chain, from raw materials to final delivery. Investing in modern enterprise resource planning (ERP) and supply chain management (SCM) systems provides real-time visibility and helps in making informed, rapid decisions, thereby improving overall operational control and innovation.

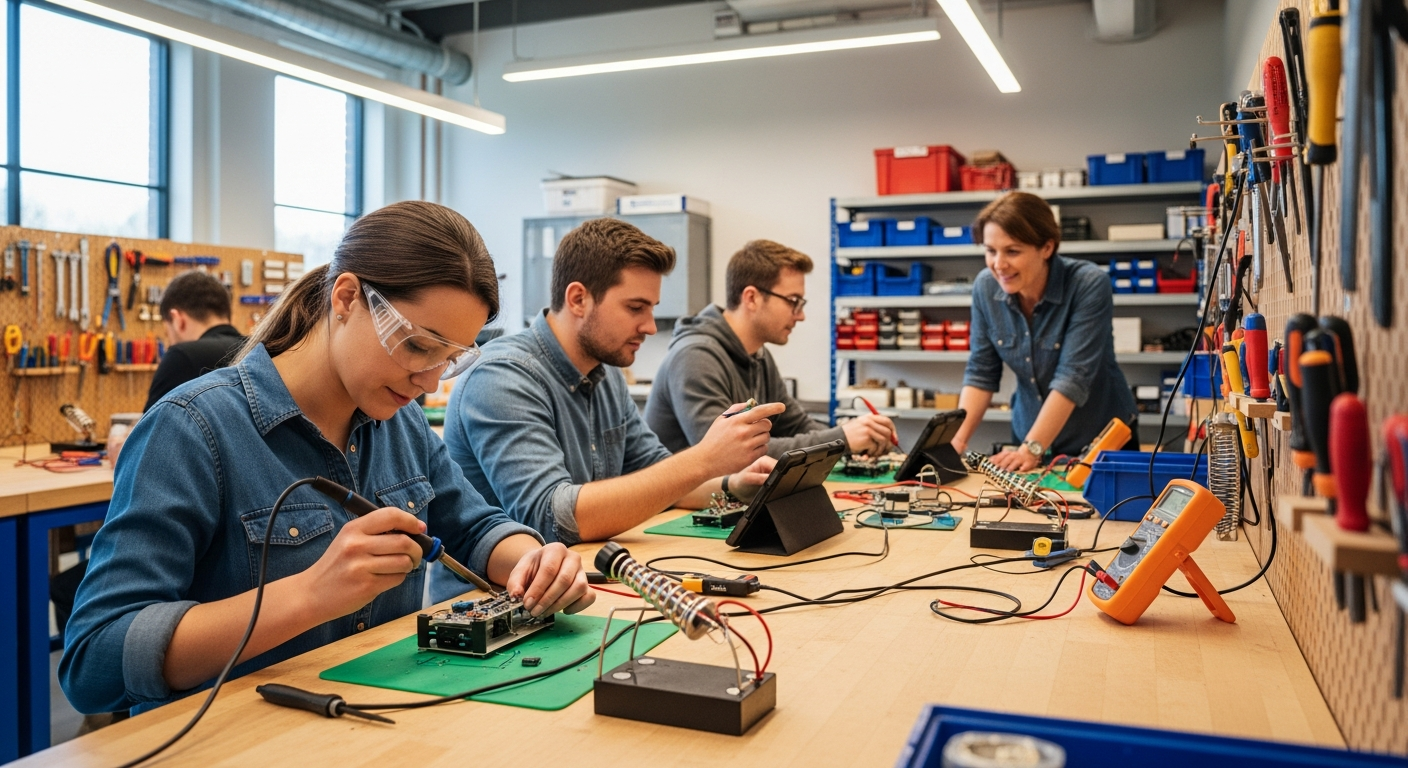

Optimizing Manufacturing and Production Processes

Optimizing manufacturing and production processes is fundamental to reducing supply chain risks. This involves adopting lean manufacturing principles to eliminate waste and improve efficiency, while also ensuring flexibility to adapt to changing market demands or disruptions. Diversifying manufacturing locations across different regions can reduce the impact of localized issues, preventing single points of failure. Furthermore, implementing robust quality control measures and fostering continuous improvement in production processes minimizes defects and ensures consistent supply, contributing to overall supply stability and industry standards.

Building Sustainable and Resilient Networks

Sustainability is increasingly intertwined with supply chain resilience. Companies that prioritize ethical sourcing, responsible resource management, and environmentally sound practices often build stronger, more reliable relationships with suppliers and communities. This long-term development approach reduces regulatory risks, enhances brand reputation, and fosters a more stable operating environment. Investing in sustainable practices and considering environmental, social, and governance (ESG) factors across the supply chain can lead to more robust networks better equipped to handle future challenges and contribute positively to global markets.

Fostering Collaboration and Information Flow

Effective risk mitigation heavily relies on strong collaboration and seamless information flow among all stakeholders in the supply chain. Establishing transparent communication channels with suppliers, logistics partners, and even customers ensures that potential issues are identified and addressed quickly. Sharing data on demand forecasts, inventory levels, and production schedules helps in coordinating efforts and optimizing supply. This collaborative approach, essential for modern commerce, builds trust and creates a more agile and responsive network, allowing for collective problem-solving and shared resources during times of disruption across the industry.

Risk mitigation in supply chain networks is an ongoing, dynamic process that requires continuous vigilance, strategic planning, and adaptive capabilities. By understanding vulnerabilities, embracing technological advancements, optimizing production, prioritizing sustainability, and fostering strong collaborative relationships, businesses can build more resilient supply chains. These efforts not only minimize the impact of disruptions but also enhance operational efficiency and contribute to long-term business success in a complex global economy.