Strategic Sourcing for Manufacturing Success

Strategic sourcing is a systematic approach to procurement that optimizes a company's purchasing power and supply chain efficiency. For manufacturing enterprises, implementing a robust strategic sourcing framework is crucial for maintaining competitive advantage, managing operational costs, and ensuring a resilient production flow. This methodology moves beyond simple transactional purchasing to a more analytical and collaborative process, focusing on long-term value and supplier relationships across the entire supply chain.

In today’s dynamic global market, manufacturing businesses face increasing pressure to optimize their operations and enhance efficiency. Strategic sourcing offers a comprehensive solution by transforming the procurement function from a cost center into a value driver. By meticulously analyzing spending patterns, market conditions, and supplier capabilities, companies can make informed decisions that support sustainable growth and innovation.

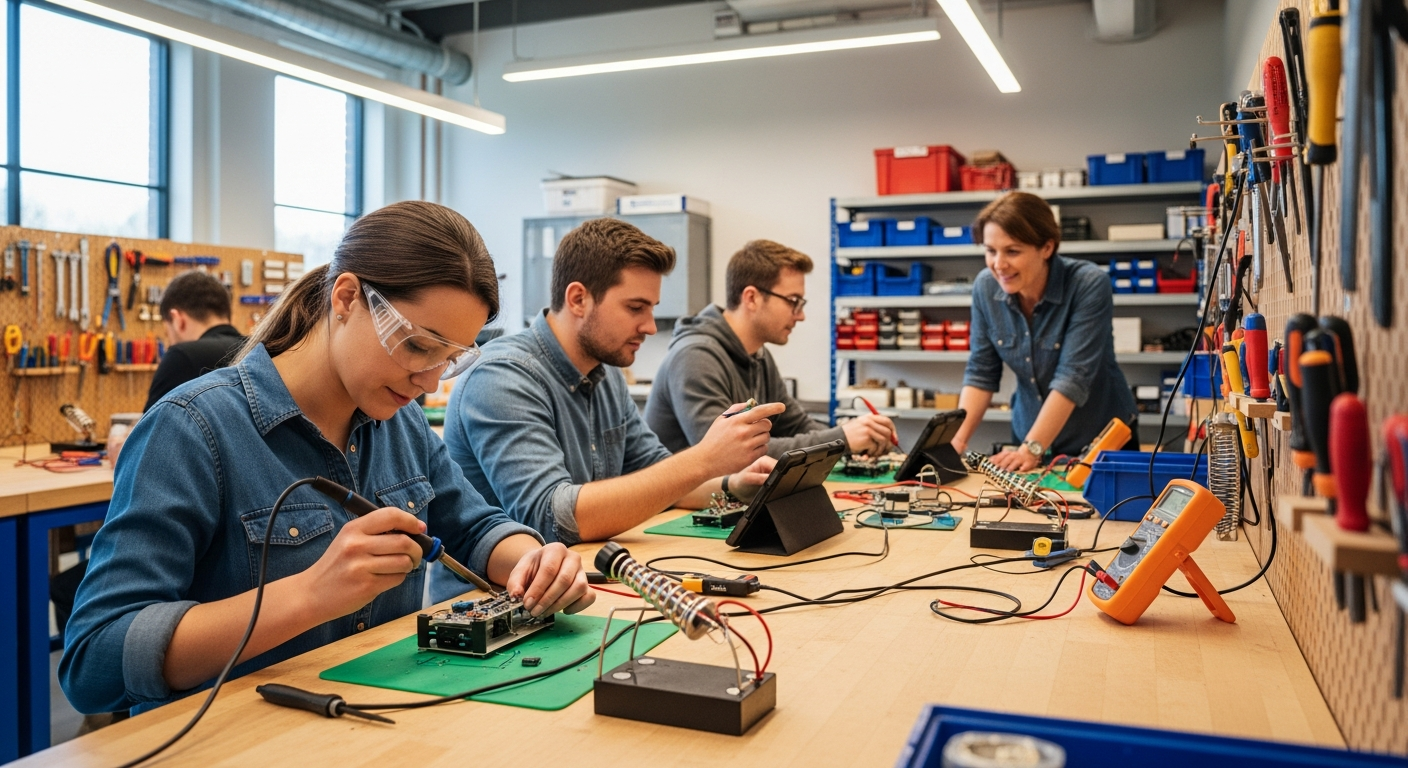

Understanding Strategic Sourcing in Manufacturing

Strategic sourcing for manufacturing involves a disciplined process of evaluating and selecting suppliers, negotiating contracts, and managing supplier relationships to achieve organizational goals. This approach considers not only the immediate cost of goods but also factors like quality, delivery reliability, risk mitigation, and the potential for long-term partnership development. It is an integral part of overall enterprise operations, directly impacting production schedules and the final product’s quality.

Enhancing Supply Chain Efficiency and Resilience

Optimizing the supply chain is a core benefit of strategic sourcing. By diversifying supplier bases and establishing clear performance metrics, manufacturers can build a more resilient supply network. This resilience is vital for navigating market fluctuations, geopolitical events, and unexpected disruptions. A well-executed strategy ensures a steady flow of materials, reducing lead times and preventing costly production delays, thereby improving overall logistics and distribution.

Leveraging Technology for Sourcing Innovation

Modern strategic sourcing heavily relies on technology and automation. Advanced analytics tools, AI-powered platforms, and e-procurement systems enable businesses to gain deeper insights into their spending, identify potential savings, and streamline the sourcing process. These technologies facilitate better market analysis, supplier performance tracking, and contract management, driving innovation in how raw materials and components are acquired. This technological integration is key to achieving higher efficiency and better decision-making in a complex economy.

Driving Cost Management and Sustainable Growth

Effective strategic sourcing directly contributes to better cost management. By negotiating favorable terms, consolidating purchasing volumes, and identifying alternative suppliers, manufacturers can significantly reduce their input costs without compromising quality. This financial discipline supports sustainable growth by freeing up capital for investment in research, development, and other areas that foster competitive advantage. It’s a critical component of a robust business strategy that aims for long-term development.

Real-World Strategic Sourcing Implementation Support

Manufacturing companies often partner with specialized firms to implement or enhance their strategic sourcing initiatives. These providers offer expertise in market analysis, supplier identification, negotiation, and technology integration. Their services range from developing sourcing strategies to managing the entire procurement lifecycle. Companies like Accenture, Deloitte, and IBM offer consulting services in supply chain and procurement optimization, helping enterprises refine their sourcing processes. Similarly, software providers such as SAP Ariba and Coupa provide platforms that automate and streamline various aspects of strategic sourcing, from spend analysis to supplier relationship management, directly supporting a manufacturer’s production and commerce goals.

Strategic sourcing is a fundamental practice for any manufacturing enterprise aiming for sustained success in a competitive global landscape. By embracing this approach, companies can not only manage costs more effectively but also build stronger supplier relationships, enhance operational resilience, and pave the way for continuous innovation and market leadership.